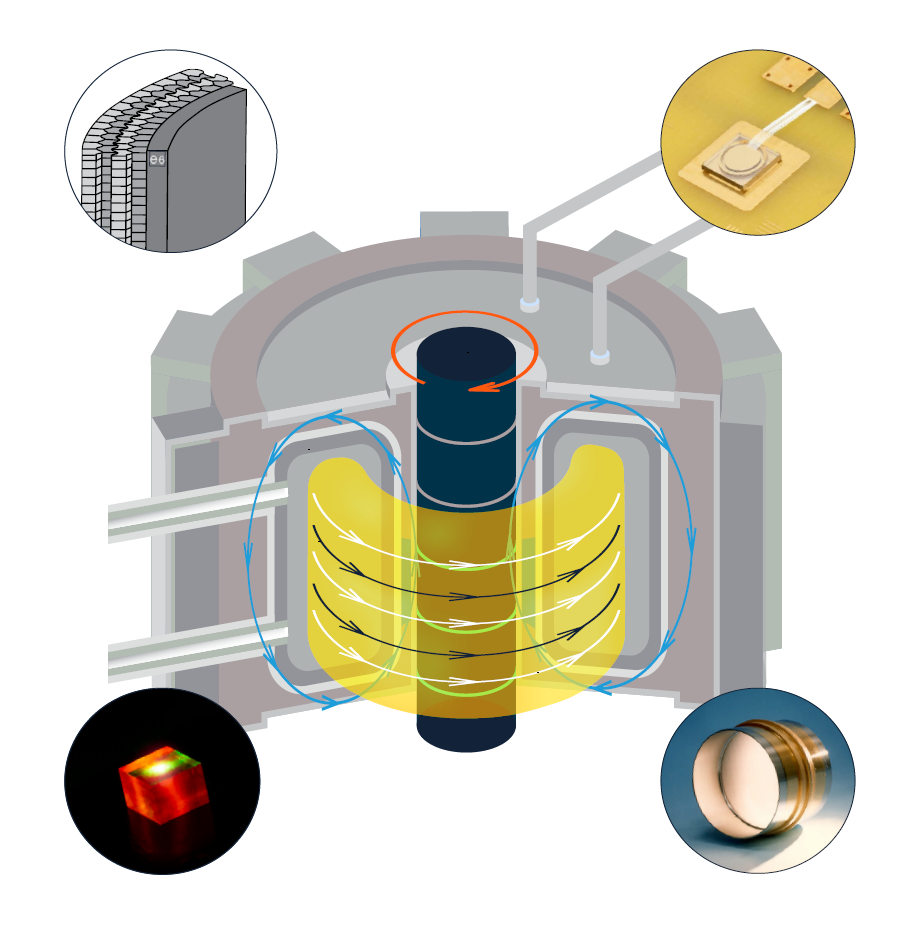

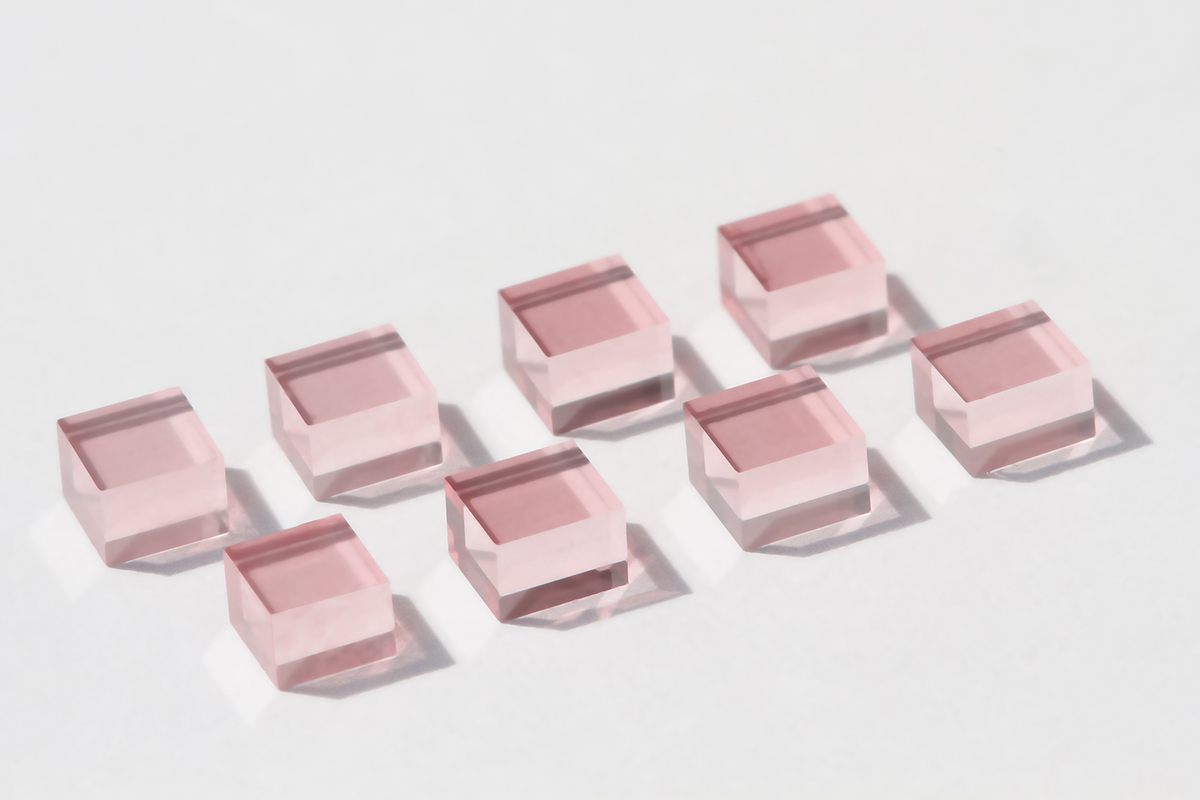

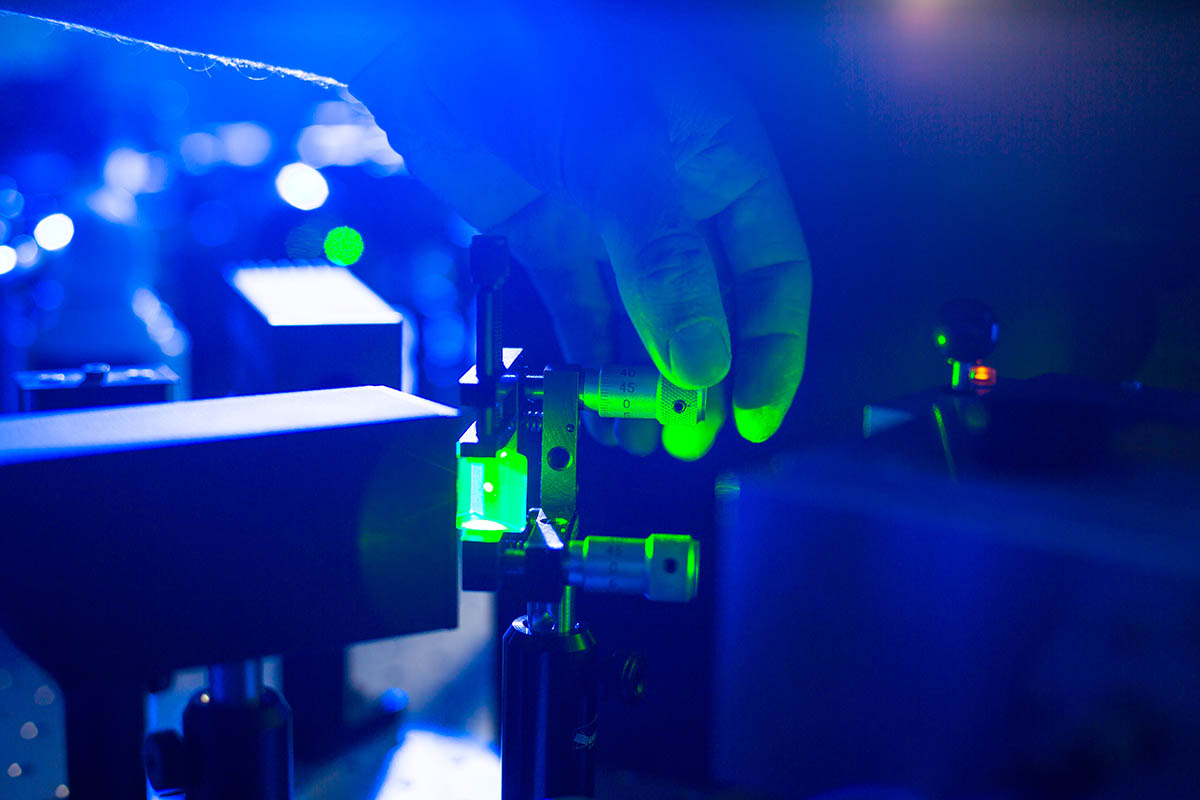

Synthetic diamond & tungsten carbide solutions for energy

Capable of withstanding extreme conditions of heat and neutron irradiation, synthetic diamond and tungsten carbide are ideal engineering materials for fusion energy. To find out more, read our brochure or contact us today at E6marketing@e6.com.