STEP-CHANGE THERMAL MANAGEMENT OF RF DEVICES USING CVD DIAMOND

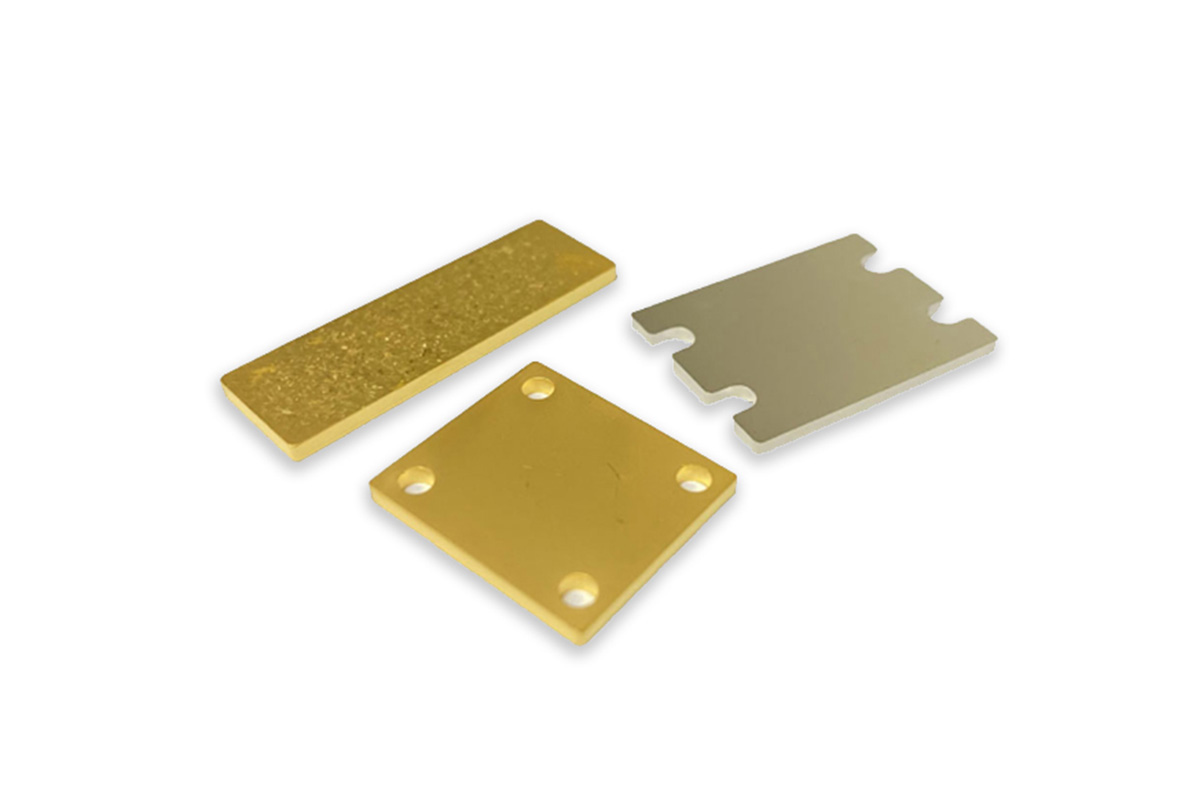

Thermal conductivity between 1000 and 2200 W/(mK) can be supplied according to your needs.

For power amplifiers, CVD diamond heat spreaders enable:

- Higher power operation for a given maximum operating temperature

- Reduced peak temperatures for a given power

- Thermal resistance drop by 30% when using CVD diamond in an RF package | Learn more through our case studies

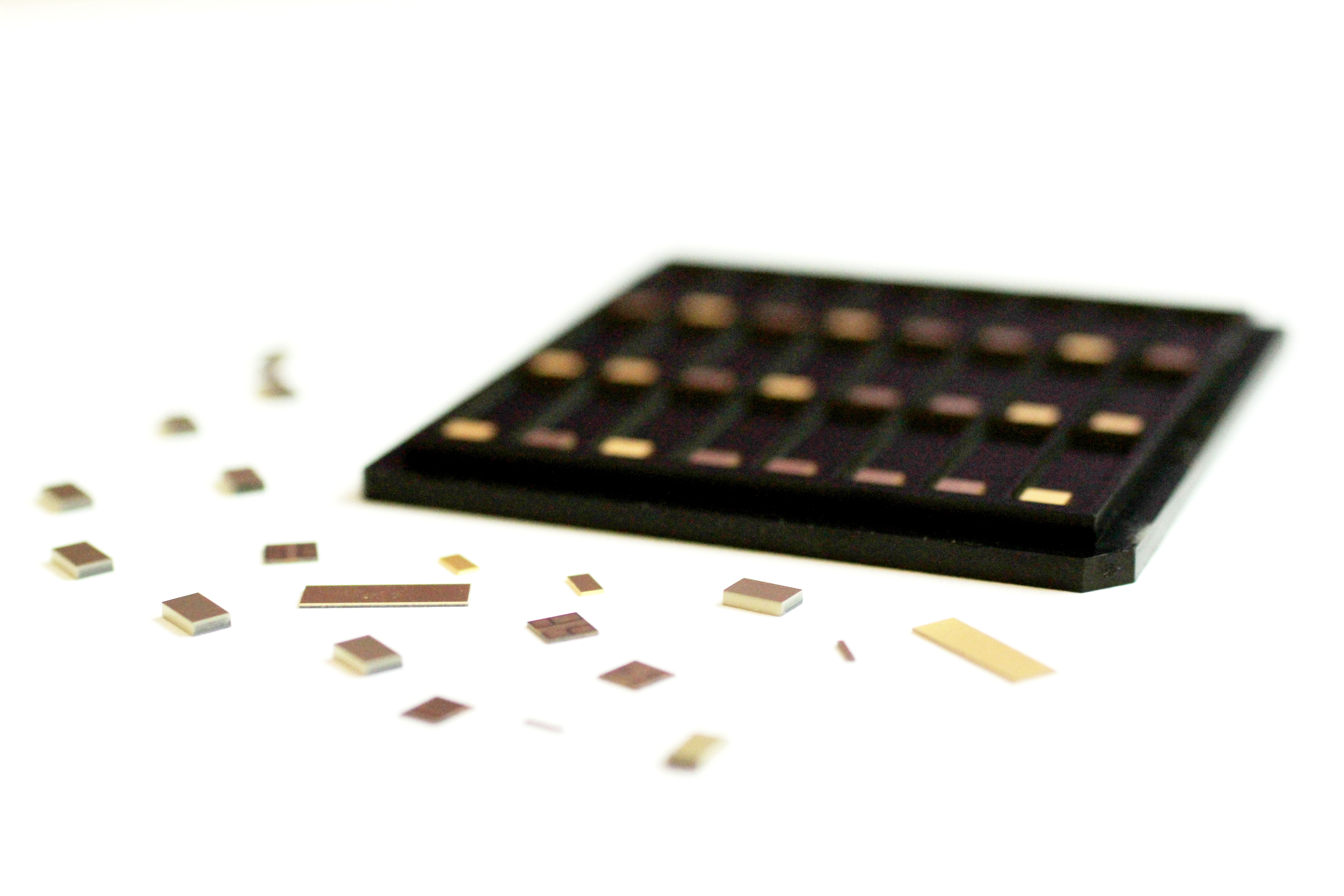

Passive radio frequency (RF) resistors using CVD diamond substrates can operate above 20 GHz, six times higher frequencies than AlN at the same power level, before parasitic effects lead to signal distortion.